Network system for facilities with multiple conveyor lines

Introducing the new and improved Mighty Lube Next Generation Permanent Conveyor Monitoring System. We expanded the networked monitoring system that our customers have come to rely on.

The Next Generation Permanent Conveyor Monitoring System is connected to the network and provides chain wear data and projections for up to 100 conveyor lines. The permanent system measures chain wear in both Link by Link and 10’ sections. This system monitors drive amps, chain speed, take-up pressure, and drive hours. It also provides data on lube cycles, reservoir levels, head voltage, and pump cycles when combined with Mighty Lube or OPCO lubrication systems.

The permanent system provides the most reliable chain wear data and projections. This system measures chain wear in both Link by Link and 10’ sections as well as monitoring drive amps, chain speed, take-up pressure, and drive hours. The Permanent Conveyor Monitoring System also provides data on lube cycles, reservoir levels, head voltage, and pump cycles when combined with a Mighty Lube or OPCO lubrication system.

Valuable new features and options:

- Added lubrication screens which time stamp lubrication cycles and changes.

- New analytical data screens, such as long term chain wear average.

- Rearrange and deactivate station addresses to group conveyors on the screen in a way that makes sense for your facility.

- Data export to .xml and .csv formats allow users greater versatility to prepare customized reports.

- Data Collection Unit can be restarted of from the software.

- Added Critical Alarms and Color Conditions

- (Chain Error) Adjustable Alarm for Reservoir Level

- New Color (Blue) notification for showing when system in Lubrication Cycle

- New Color (Orange) alert for switch error requiring recalibration or cleaning

- Improved settings allow for more flexibility of email notifications.

- Scrollable graphs provide the ability to see specific data more accurately.

- Updated user-friendly dashboard with more efficient features.

- Time stamped notes field to record changes and conditions on individual systems.

- Compatible with Windows 10 as well as most previous versions of Windows.

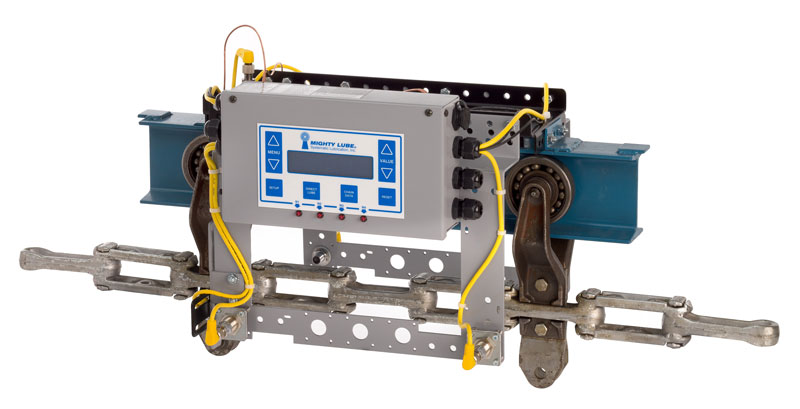

Permanent Conveyor Monitoring System Models

- 9100M (Richards-Wilcox Enclosed Overhead Conveyor)

- 9101M (Unibilt/Rapid Enclosed Overhead Conveyor)

- 9103M (3” Overhead Monorail Conveyor)

- 9104-4M (4” Overhead Monorail x458 Conveyor)

- 9104-6M (4” Overhead Monorail x678 Conveyor)

- Additional models available for Inverted and Specialty Conveyors

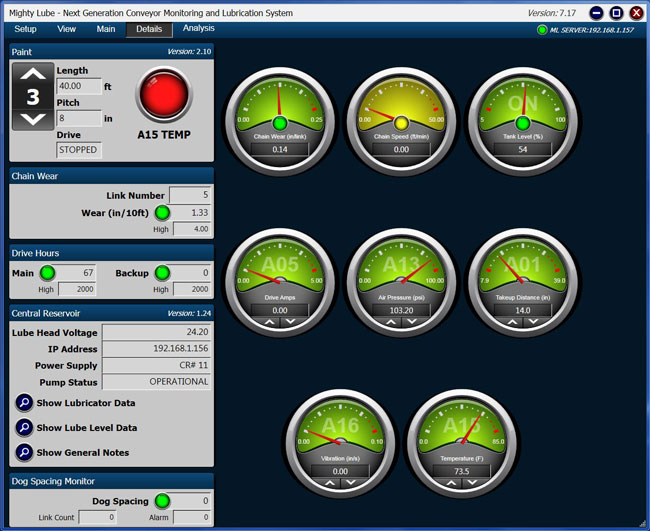

Details Page

Easy to read gauges display real-time data with system specific detail. Gauges are activated with the head unit setup. Displayed gauges vary with the conveyor monitor option.

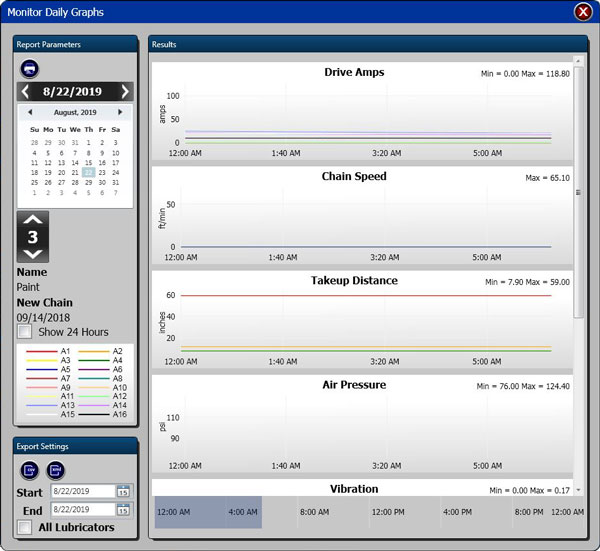

Monitor Daily Graphs

This window displays graphs for the following conveyor data:

- Recorded Drive Amps

- Air Pressure

- Distance

- Chain Speed

- Vibration

- Temperature

- Lubrication Cycle*

Chain Wear Screen Detail – 10 ft

Accumulated 10ft chain wear data in both graphical and numerical form.

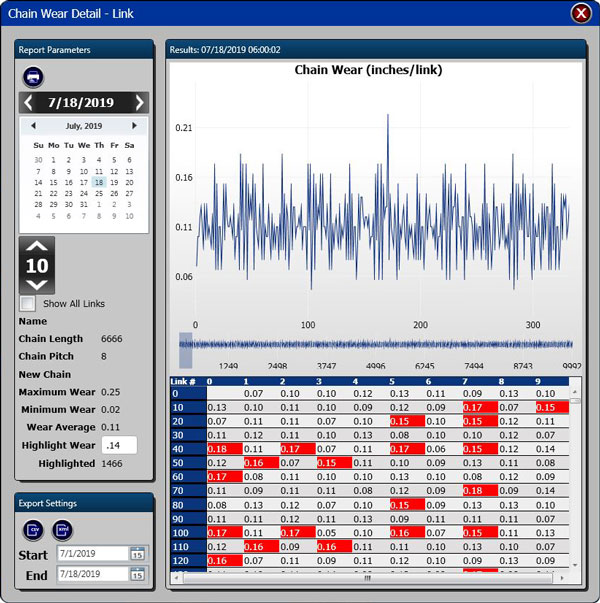

Chain Wear Screen Detail – Link

Contains accumulated wear data by link, which is displayed graphically and numerically.

Chain Wear Screen Average

Accumulated chain wear data (in/10 ft.) average as a graph with numerical report.

Long-Term Chain Wear Screen Average

Chain wear data (in/ 10 ft.) 30, 60, and 90 days’ average in a graph and numerical report.

Chain Wear Screen Projection

A graphical/numerical projection of 10ft chain wear based on accumulated data and wear characteristics.

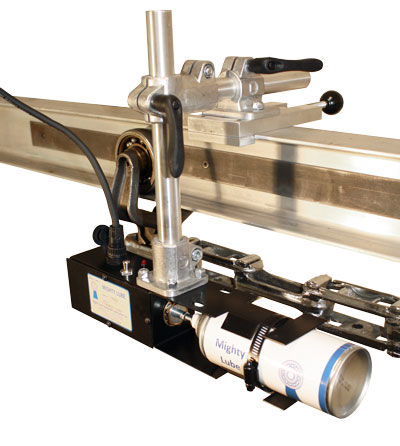

Optional Paint Marker Add-On

- Allows for automatic marking of worn links or areas that exceed company set parameters

- Portable – can be moved from one conveyor to another

- Power and control provided from Monitoring Head Unit

- Utilizes Standard Aerosol Paint Can (not included)

- Includes 8-ft. control cable

- Available for Inverted and Overhead Conveyors