Easy-to-transport chain wear monitoring system for facilities with multiple conveyor lines

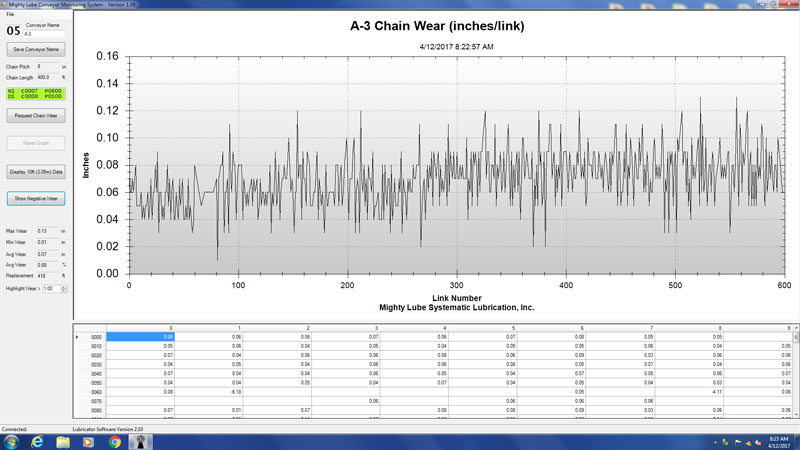

Mighty Lube developed a new Next Generation Portable chain wear monitoring system for facilities with several conveyor lines spaced far apart. This system was engineered with the customer in mind. It has a lightweight frame and battery power allowing you to easily move the unit from one conveyor to another. The portable unit includes a Windows tablet that is preloaded with user-friendly software which provides both link by link and 10-foot data.

If you have multiple lines that are located in the same building within a close proximity, we recommend our Permanent system.

Portable Monitoring System Features:

- Monitors Conveyor Chain Wear – Link by Link and 10’ wear

- Pinpoint exact location of worn areas

- Detects direction of chain travel

- Display and print graphs and data

- Utilizes the latest Patented Technology

- Multi-line (Portable) Software License and Program Included

- Includes Windows-based tablet with USB Connection

- Clamps on conveyor rail for ease in mounting

- Adjustable to accommodate different chain sizes

- Lightweight aluminum frame

- Rechargeable battery provided

Portable Models

- 6304-4/6M (4″ overhead monorail x458/x678 conveyor)

- Framework available to adapt for 3″ overhead monorail x348 conveyor

- Additional framework available for inverted conveyor.

- Optional Paint Marker Add-on