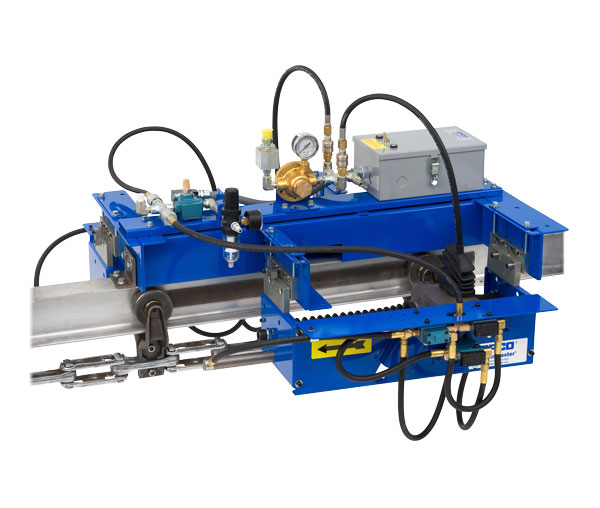

OPCO® OP-201 Sealed Trolley Greaser

Conveyor monitoring has many benefits. Some of the major benefits include extended equipment life, lower energy consumption, and accurately pinpointing chain wear. The OPCO® OP-201 trolley wheel greaser automatically greases the bearings inside of sealed power trolley wheels while the conveyor is running under normal conditions. The OP-201 operates pneumatically to accurately deliver metered shots of grease into sealed trolley wheels of overhead monorail conveyors. Specifically, this greaser works by injecting grease into each hydraulic fitting during a lubrication cycle. In addition, a timer, or a counter, can control the duration of the cycle.

Benefits of using the Automatic Sealed Wheel Greaser:

- Reduces downtime and manual labor operations

- Extends the life of conveyor components

- Eliminates surging caused by non-lubricated and worn wheels

- Allows closer spacing of product, which in turn increases productivity

- Conveyor runs smoother, keeps product from swaying

- Reduces possibility of injury on the line

- Helps reduce drive power requirements

- Reduces wasted grease by cleanly and precisely injecting a metered amount into wheels

- Fitted for overhead or inverted conveyor types

OPCO Lubrication Systems Inc also offers automatic greasers for other conveyor types. Visit opcolube.com to see more available products.