When it comes to keeping your conveyor system operating at peak performance, monitoring is just as important as lubrication. Without proper monitoring, early signs of wear, chain elongation, and drive issues can go unnoticed, leading to costly downtime and unplanned maintenance. The right monitoring system helps you detect problems before they turn into failures, allowing you to plan maintenance and protect your investment.

At Mighty Lube, we design conveyor monitoring systems that deliver accurate, real-time data to help you make smarter maintenance decisions. But with different system types and capabilities available, how do you know which monitoring solution is right for your facility? Here’s a step-by-step guide to help you choose.

Step 1: Know Your Conveyor Type

Our monitoring systems are designed to work with specific conveyor styles and applications. Understanding your conveyor type is the first step to finding the right fit.

Power & Free Conveyors

For systems that handle independent carriers and multiple load zones, our Permanent Conveyor Monitoring tracks chain wear, drive performance, and system health across each line. It’s ideal for high-traffic environments where uptime is critical.

Enclosed Overhead Track Conveyors

Our 9100M and 9101M Permanent Conveyor Monitoring overhead enclosed track monitoring systems measure chain elongation and detect roller wear within tight track designs. These systems are commonly used in finishing lines, paint systems, and manufacturing facilities where cleanliness and precision matter.

I-Beam Conveyors (Monorail)

For traditional I-beam systems, our I-beam Permanent Conveyor Monitoring units track chain wear and link performance with accuracy. These systems are built to withstand heavy-duty industrial environments and can alert maintenance teams when replacement is needed.

Step 2: Consider Your Facility Size and Operation

Your monitoring needs depend on how large your facility is and how many conveyor lines you operate.

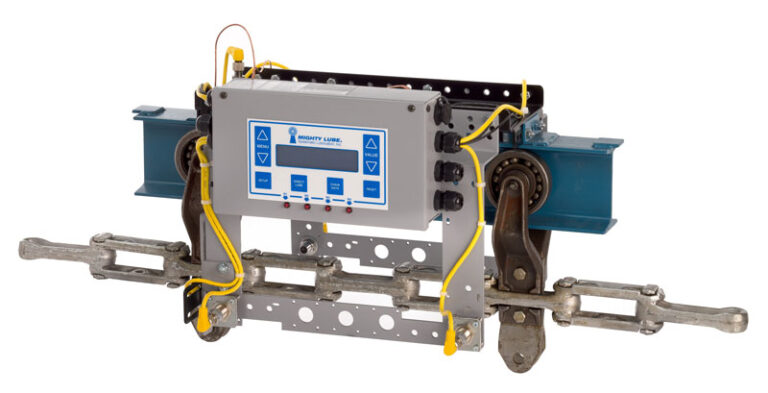

The Portable Mighty Lube Monitoring System provides smaller operations essential data without requiring complex networking or additional infrastructure. It’s a great way to start collecting chain wear and fault information on individual lines.

For larger facilities or multi-line operations, our Networked Permanent Conveyor Monitoring Systems offer centralized data collection and analytics. With these systems, all conveyor data is stored and viewed from a single dashboard, giving maintenance teams instant visibility into performance across the entire plant.

Step 3: Look at the Features That Matter

- Real-time chain wear measurement for multiple conveyor lines

- Drive and take-up monitoring for performance tracking

- Temperature and vibration sensors to detect mechanical issues early

- Fault and deviation reporting with automatic alerts

- Integrated software for easy data viewing and maintenance planning

- Compatibility with plant networks and PLC systems

Step 4: Think About the Long-Term Benefits

- Early detection of chain wear and potential failures

- Reduced unplanned downtime

- Longer conveyor life and lower maintenance costs

- Increased operational visibility for maintenance teams

- Smarter scheduling and planning for preventive maintenance